Aerial tram used at the gypsum quarry near

Sun City, Kansas.

Photo courtesy of Elloise Leffler

Comments about the Gypsum Mining and Quarrying Operations

By Nate Massey

at Sun City, Kansas(E-mail from Nate Massey to Kim Fowles, 16 January 2007.)

The aerial tram operated a lot like the ski lifts do today except it was in use in the 20's and 30's or maybe before, the gyp was quarried from the surface in the beginning and later mined. The quarried land started a short distance west of the junk yard curve south of Sun City and extended to where the present site is now and where the entrance tunnels went into the hills southward.

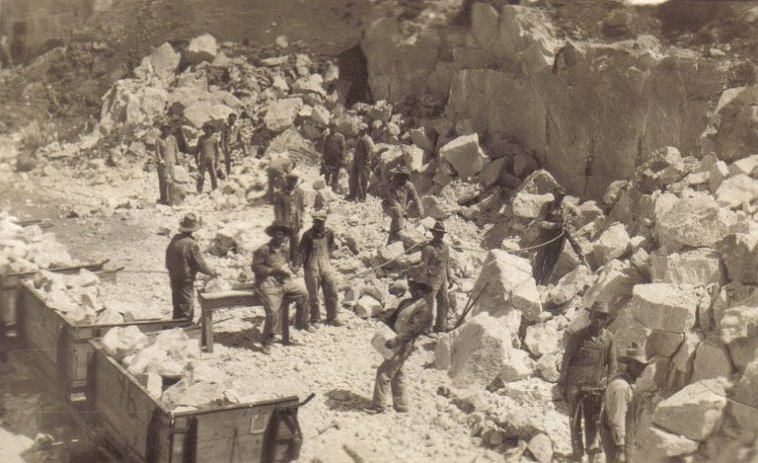

The quarrying was hand loaded and I think at one time there were about 100 or more employees engaged in the operation, each loader was issued round brass tabs with their particular number stamped in it and they would attach it to a snap catch hook on the side of the car he loaded and he was given credit for that number of pounds or tons per day and they were paid on their output, so the bigger stronger guys that could lift the heavier rocks naturally could get more pay, there was also lots of shoveling on the small stuff. As usual there was always a few who would remove tags and replace with theirs until they got caught.

The mine cars would hold about a ton and were pulled to the crusher building which was located on top of the hill on the west bank or cliff of the junk yard canyon there it was crushed into about 2 or 3 inch diameter particles and stored temporarily into a holding bin which had a chute with a control gate on it.

The tram cable if I remember correctly was in the 1.5 inch diameter range and was a closed loop which had about a 10 foot diameter wheel on each end , the south end was at the hill described before at the top of the hill and the dump end terminal was located at the railroad spur on the west side of Sun where the company houses called Mexico is located, the buckets which held approximately 1000 lbs. were loaded from the chute at the top of the hill and were hand dumped at the bins at the Sun City terminal into hopper cars for shipment to the mill at Medicine Lodge.

I don't know the exact distance between terminals but I would estimate about 3/4 of a mile or more.

If I remember correctly they tried to space the buckets out at about 500 to 1000 ft. intervals on the tram line. I do remember the cable breaking one time and spilling all the buckets.

I remember Roy Harris was the dump operator at the dump end, don't know who was the chief on the other end.

I remember Bill Hugh Froman - whose dad was a understudy of Mr. Marquis, the mine superintendent - and myself and several other dummies used to get into the mine buckets and hitch a ride, it was definitely against the rules and didn't happen very often.

Dave might have some more specific info. on dates, manpower, etc. as he worked in the offices of the mine for awhile.

I'll send another letter on Hugh Froman and Sam Shepler.

Thanks for writing,

(E-mail from Nate Massey to Jerry Ferrin, 25 January 2007.) Jerry, really appreciate the data on the mines, I worked there for about 6 months or so when K-state was so overloaded in 1948 that you couldn't get in the curriculum subjects, It was very interesting, a real diversity for me as I was a fill in for all the regulars when they went on vacation so was active in almost all the operations of that time.

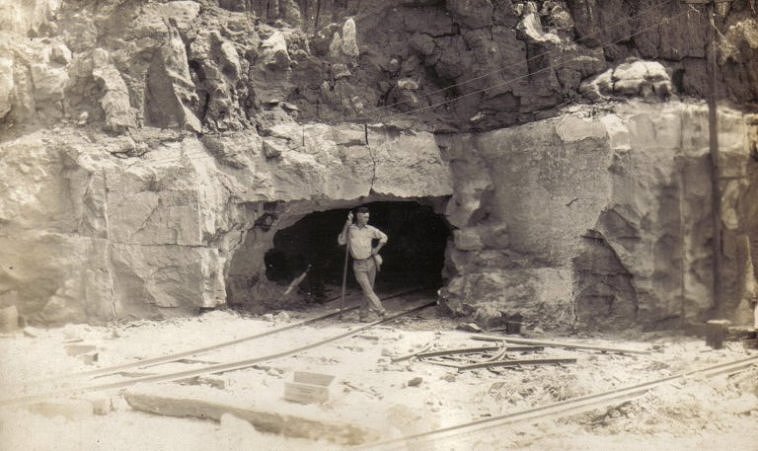

At that time the operation was operating nearly 1.5 miles into the mine and was spread out probably about the same distance. The tunnel going into the mine was rather small at the entrance , probably 10 to 12 feet wide and the tunnel narrowed to less than 8 feet as you headed south into the mine, inside the height varied and in some places was 15 to 20 ft. high and some rooms were nearly 40 feet wide.

The operation at that time started with a face of rock preferrably 24 ft. wide and 12 ft. high which was first undercut by a mining chainsaw at the floor level that cut a kerf about 6 inches high and if I remember correctly, 10 to 12 ft. deep , just like a large wood cutting chain saw, this would let the explosive blast from the 24 drilled blasting holes drop before blowing outward, Jim Shellenberger and Gene Beckendorf were the operators of this machine until a roof fall injured Gene and ended his mining career.

Following the undercutting the drillers, _______ Brown and Howard Janson drilled the blasting holes with two large 100 lb. drills mounted on vertical supporting columns, I think the holes were drilled in about 12 feet and were drilled in patterns where the center sets of holes were angled towards the center to form a wedge , these holes were then tamped in with several sticks of dynamite, the blasting caps were electronically ignited and were timed in microseconds to blow the center section out first so the side blasts could cave into the gap at the center, and go down into the 6 inch kerf at the bottom created by the undercut.

The blasting was always done at quitting time in the evening and huge fans were used to venilate the dynamite fumes from the mine. The powder fumes caused severe head aches otherwise. By the way, the temperature in the mine was a constant 68 to 70 degrees and never varied, the rock was very white so the working situation was pretty ideal, except no sunshine.

Jerry, will send this for now and will continue it at a later time.

(E-mail from Nate Massey to Jerry Ferrin, 26 January 2007.) I'll try to funnel you more info on what I recall about the gyp mining at Sun City, the head driller was Art Brown and Howard Janson was his assistant, the center blow out was called the keystone or wedge by the Sun crew.

After the blast and airing out, if there weren't rail tracks laid, that was accomplished; about all the crew had to help with that as everything was shut down on rock movement until that was achieved.

At that period of time the cars were loaded with a skip loader ran by Earnest Larkin and his assistant Frances Tuefel, Earnest at that time had the most seniority in the mine, and the loader was the top rated job.

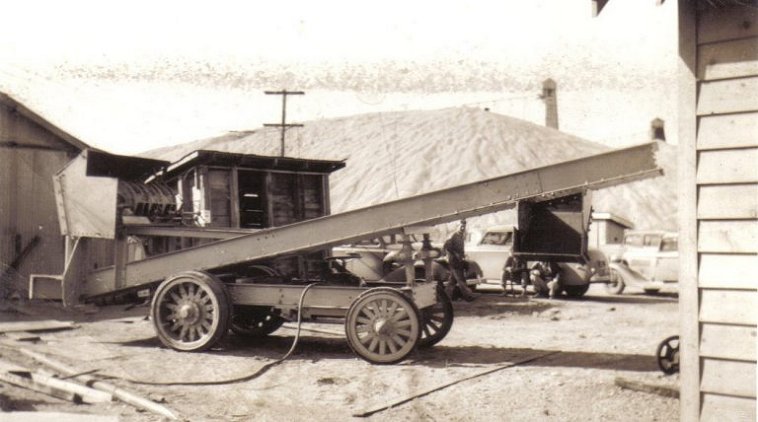

The skip loader was a large framed ramp unit that had a large multiple winch power unit, track driven, that had a ramp extending over the rails, the steel mining cars were backed under the ramp and pulled into place originally by a mule, driven be George Harmon, and eventually replaced by a D4 Cat with front loader. I think Orgal "WeeHaw" Keller ran the Cat originally.

The skip loader had a very heavy drag blade or scoop similiar to an old fresno only made from steel almost 6 inches thick and about 6 feet wide by 3ft in height, there were cables fastened at each end on the back side and one pulling cable attached to the tongue on the front toward the loader, the rear cables were run through snatch blocks secured in the two far corners of the blasted room and back to the loader winch, each cable could be controlled individually but it required a lot of coordination to keep the bucket in synch , there was a right, left and retrieve control, all done with manual winch lever controls similiar to a Caterpillar tractors steering levers. The unit was electric powered.

The mine cars were all steel and each held about 6000 lbs. if I remember correctly, and a train was made up of 16 cars; they were pulled by power units, 4 wheel drive, that were manufactured by a company by the name of Plymouth, no connection to the automobiles. The oldest unit still had the orginal 4 cylinder gas engine in it and the other identical unit had a Cat engine equivalent to a D6 tractor - by the way, the old unit had more snap than the new one did.

The two engine drivers were "Shorty" - Orin Houchins - and Glen Hogard. Glen was promoted to mine foreman about the time I was there so I filled in until I think Loren Bodenhamer took the job.

The cars were then pulled out to the crusher track and then the outside train of emptys was pushed back into the mine.

On the crusher end the cars were uncoupled and let "gravity roll" onto the crusher dump which rolled the car over on its back to dump the rock into the hopper over the crusher, the smaller rocks would fall straight through the rotary crusher and onto the 48 inch rubber conveyor belt to the bins above the Santa Fe hopper cars, the conveyor shed is shown in one of your pictures and must have been at least 500 or more feet in length, there was a large steel conveyor chain elevator that took the larger rocks up to a moving steel platform conveyor about 20 feet above the crusher floor, these oversize rocks were then jackhammered into a size that wouldn't shear the pins, which were large 3 to 4 inch wooden dowels; I think there must have been at least 10 to 12 of them in the collar. At that time anhydrite had to be hand-picked and dumped onto a separate conveyor and dumped into a side canyon.

Lester "Dog" Davis was crusher operator, Claude "Bacon" Pearson was his assistant and operated the picking table, Joe Harrison was the car loader.

Sam Shepler was the Superintendent; Tudy Shepler, his wife, was secretary; Hugh Froman was shop foreman; Homer Venters was electrician and there were several other temporary hands.

If I remember correctly they loaded out 3 to 6 hopper cars per day.

By the way since there was so much dynamite used, not only for blasting, but for "dobie busting", (large 4 foot plus boulders). In this case, since the explosive force of dynamite is in downward force, we would lay a stick or two on top of the boulder, put about 20 lbs. of mud or sand on it, light a 12 inch slow burning fuse and go hide behind a pillar until she blew.

The miners also used random sticks to split the large cottonwood tree trunks that Dad and Uncle Ray would give the miners for their heating stoves. Some was even used by Bill Hugh Froman and an unknown ranch kid to do a little fishing on occasion, which sure beat diggin' worms and baitin' hooks. When one or two sticks wasn't enough, several more would lift the whole river bed up about 4 feet and you could look right under it, that only happened once.

Thanks again, Jerry.

Comments about the Gypsum Tram, Mine and Rail Spur

By David Massey

at Sun City, Kansas(E-mail from David Massey to Kim Fowles, 15 January 2007.)

The destination of the tram was "Mexico" where the gyp was loaded in rail cars for its trip to the mill in Medicine. The origin of the tram was on the hill about a mile east of where the mine/crusher is now. They quit it after they discontinued quarrying and started mining underground. I think the rail spur was laid up the the mine prior to 1935 as it was in place when I started to school. But I'm sure the tram was being used when the boys started as they used to talk about the construction crews living in tents as they ran the spur up through your G-G-grandfolk's land. I think it took a couple of years as they used horse/mule power.

About "Mexico" at Sun City, Kansas

By John Robert MasseyThe city deported the Mexicans back to Mexico in about 1930 or '31 because they had jobs that the citizens needed. Most of them had worked either on the section gang or a few at the mines. They had a separate school for them down in the "Mexico" part of town. Mrs. Quinby taught all of them in one room. I don't know if any of them ever went past the eighth grade or not. I don't think so. -- excerpt from "Memories of Sun City, Kansas". The complete essay is here.

(Also see Sun City School Pupils, 1920-1921)

Workers in a gypsum quarry near Sun City, Barber County, Kansas.

Photo from the collection of Beth (Larkin) Davis.

View Larger Image

Miner stands in the entrance of an adit of a gypsum mine near Sun City, Barber County, Kansas.

(An adit is a horizontal mine opening which dead-ends in the earth; a tunnel is a horizontal mine opening with both ends open to the surface.)

Photo from the collection of Beth (Larkin) Davis.

View Larger Image

Equipment at the gypsum quarry or mill near Sun City, Barber County, Kansas.

Photo from the collection of Beth (Larkin) Davis.

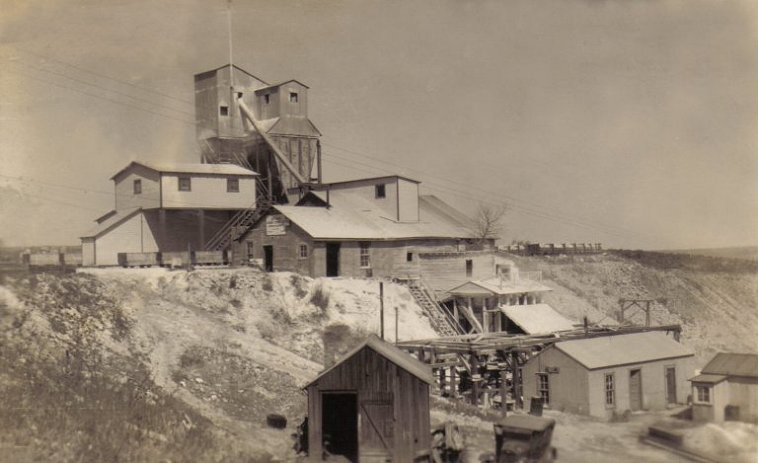

Best Bros. Keene Cement Quarries buildings near Sun City, Barber County, Kansas.

Photo from the collection of Beth (Larkin) Davis.

"The set of buildings that has the bins above it is the crusher building and I believe it is the present one just outside the mine entrance although they had added onto it and made some changes in later years. I'm guessing these pictures were taken in the early 1930's, probably not too long after they had gone from quarrying to mining." -- Comment by David Massey, 20 January 2007.

Best Bros. Keene Cement Quarries buildings near Sun City, Barber County, Kansas.

Photo from the collection of Beth (Larkin) Davis.

Gypsum quarry or mill workers with some family members in front of a bus near Sun City, Kansas

Photo from the collection of Beth (Larkin) Davis.

View Larger Image

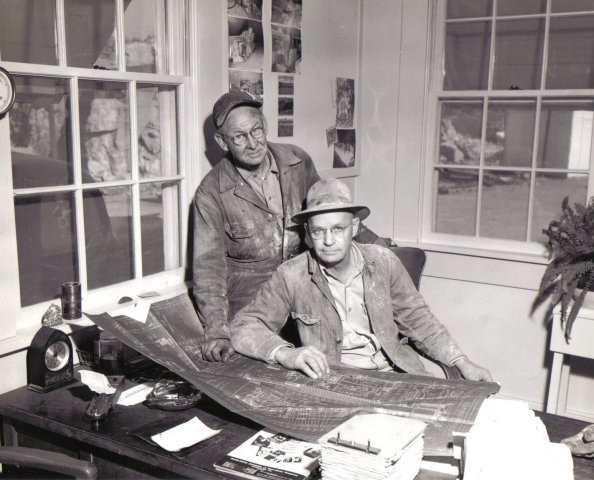

Hugh Froman, at left, and Sam Shepler in the office of the National Gypsum Company mine

near Sun City, Barber County, Kansas, in 1954.

Photo from the collection of Beth (Larkin) Davis.

Sam Shepler and Hugh Froman

By Nate Massey(E-mail from Nate Massey to Kim Fowles, 15 January 2007.)

Sam Shepler was superintendent of the mines - following Mr. Marquis - who was a mining engineer and, to most of us cow country kids, very impressive in his high shiny riding boots calvary pants and hat. He drove a new Buick touring car with spare tires on each side of the hood with chrome covers. He lived with his daughter Barbara in the company house near the terminal building south of the river. I think they left the same year that Barbara finished high school, I believe in '36.

Sam Shepler was a veteran of WWI and evidently in the engineers, I believe he had some advanced schooling in engineering also but am not sure. I know he was proficient in the civil aspect of surveying, etc, because I manned the stadia rod and helped him lay out tunnels the short time I was employed there. Sam was a really neat guy and was active in what civic activities that Sun had at that time and was in charge of the civil defence activities during the war and active in VFW at Pratt.

Hugh Froman and his brother Bill were in the mechanical and electrical end of the mine program. Bill was Mr. Marquis's right hand man over the mechanical part of the operation which was rather extensive, Hugh actually ran the shop and usually had 2 or 3 helpers. Mining at that time was a rather hard rock system with lots of drilling, 48 cases of dynamite per day, skip loaders and one D4 Cat cleanup tractor, plus 4 to 5 miles of railroad track, Narrow gauge, 2 Plymouth locomotives, etc.

I worked in the mines for about 8 or 9 months after getting out of the army, was involved in a train collision , broke a leg, went back to college and so forth.

Here is Sam Shepler, Medicine Lodge mine superintendent and long time employee of the company.

When National Gypsum Company bought the Best Brother Keene's Cement plant at Medicine Lodge, Kan., one of the oldest and ablest employees of the plant was Sam Shepler. He had worked his way up in the plant to the position of mine foreman. After 28 years at Medicine Lodge, Sam is mine superintendent.Sam started as a mechanic at the plant in 1916. In 1917 he volunteered for the Army, served overseas with the Engineers, and was discharged in July, 1919. Sam came right back to the work he liked best at Medicine Lodge.

After two years work on a mining operation for the company in Sun City, Sam returned to the Medicine Lodge plant and worked as a driller, mechanical shovel operator, and shop mechanic. Having built up experience through these years, Sam was made foreman of quarry No. 5, and later general quarry foreman.

When the company changed from quarrying the rock to mining, Sam's valuable experience made him able to fill the job of mine foreman, and in March, 1942, he became mine superintendent.

Sam is married, owns his own home, and gives all the time he can to the Veterans of Foreign Wars.

(National Gypsum magazine, May 1944 - news clipping from the collection of Beth (Larkin) Davis.)

Gyp Mill near Medicine Lodge, Kansas. Photo taken in 1909.

Photo courtesy of Ed Rucker.

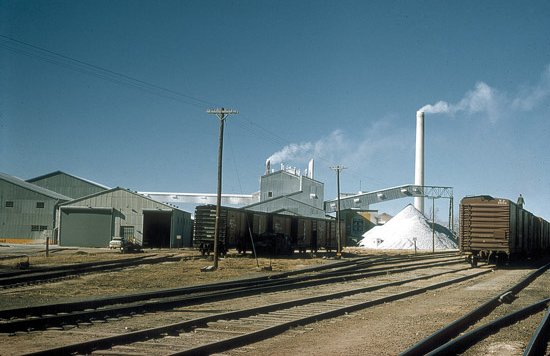

National Gypsum Plant, Medicine Lodge, Kansas.

Photo by Robert Sawin, courtesy of the Kansas Geological Society.

National Gypsum Plant, November 1962.

Photo by John Charlton, courtesy of the Kansas Geological Society.

Pioneer Mine, November 1962.

Photo by Grace Muilenburg, courtesy of the Kansas Geological Society.

The Gypsum Mine and Mill in the News 1935 News Review, Barber County, Kansas - "Jack Best heads National Gypsum Association."

1936 News Review, Barber County, Kansas - "Gyp Mill forces were given banquet by Mr. Clifford Histed, vice president and..."

1937 News Review, Barber County, Kansas - "Medicine Lodge folks visit gypsum mines at Sun City, and have dinner in the mine as guests of the Best..."

News Review, 1938, Barber County, Kansas - "Fire damages small warehouse at Gyp Mill. John C. Best to National Gypsum company of Buffalo, New York..."

1941 News Review, Barber County, Kansas - "The National Gypsum Company owners of the Medicine Lodge plant, and manufacturers of wall and..."

1942 News Review, Barber County, Kansas - "D. C. Chads, superintendent of the National Gypsum company plant here, has accepted a position with an ammunition plant..."

1943 News Articles, Barber County, Kansas - "Medicine Lodge National Gypsum Company plant receives safety award from C. M. Pollard..."

1944 News In Brief, Barber County, Kansas - "Ralph Knight hurt at Gyp Mill Thursday. National Gypsum wins first place in safety contest."

References to the Gypsum Mine and Mill Elm Grove "Red Rock" School, Barber County, Kansas - "This school house was in the Kling area between Belvidere and Sun City. Notice the Gyp Mill on the right!".

Kling, Barber County, Kansas - "Kling - Between Belvidere and Sun City. This was a company town set up to mine gypsum. The mine was an "open mine," and used horses, mules, and hard labor..."

Heritage Center, Barber County, Kansas - "National Gypsum contributes wallboard for Heritage Center."

Townships, Barber County, Kansas - "In the central and west portions large deposits of gypsum rock are found, from which a quality of cement is manufactured..."

Cat Wagons at Sun City, Kansas - "I don't know if any cat wagons were ever headquartered at Sun or not but there was an old man that lived at Sun when I was a kid who had run one out of Kiowa in the early days. His wife (legally) and another lady was his stable. Their most regular route was payday at the gyp quarry which at one time worked over a hundred men, many of which were single. They, along with the single cow-boys, probably was their regular clientele.

Some of the employees of the Gypsum Mine and Mill: Fola Mae (Melkus) Axline - "After graduating from high school, she worked for National Gypsum as a telegrapher..."

Joe D. "JD" Brownell - "... he worked at National Gypsum Company for 35 years in Medicine Lodge."

Samuel Silvester Lincoln Davis - "He will be greatly missed among his fellow workers at the Gyp Mill with whom he has worked these many years."

Bill Franklin Garten - "Jerry... works at National Gypsum Company as a Wet End Leader."

Glen LeRoy Hogard - "He was an employee of the National Gypsum Company and had lived in the Sun City area most of his life."

Ralph Knight - "Ralph Knight Hurt Thursday - The first serious accident to occur at the National Gypsum Company plant here in some time happened Thursday evening..."

Tonka Jo (Mills) McElyea " She was a sales supervisor of National Gypsum Company in Medicine Lodge..."

Allen Lee Schnelle - "...range of jobs including truck driver, lineman for Pacific Railroad, lawn care, and at National Gypsum Company."

"Ralph Sheldon went to work with a harvesting and threshing crew, and soon Bessie was running the cook shack, feeding the crews. After harvest was over, the Sheldons operated a caf', which was located in a frame building on the site that is now part of Dirks Copy Products. Bessie was a superb cook - and her pies were especially popular. After the birth of son, Ray, in 1910 Ralph Sheldon went to work for Best Bros. Keene Cement. The family moved to Kling - a gypsum workers' "suburb" of Sun City. The Sheldon family of three lived in three rooms of a duplex; Ralph's widowed mother and a brother lived in the other half of the house." -- Excerpt from the 21 October 2007 Meandering column by Bev McCollom, published in

The Gyp Hill Premiere , Medicine Lodge, Kansas.Samuel Jefferson Shepler - "Samuel Jefferson Shepler, 70, retired mine foreman for the National Gypsum Company, who died Saturday at Lake City..."

Homer Venters - "During winter months, Homer did free lance work for National Gypsum Company and eventually became a fulltime electrician and photographer..."

Wallace H. Willms - "He was a National Gypsum panel operator for 21 years."

Also see:

Photos of Barber County, Kansas, from the Kansas Geological Society

Cowboy Rock near Sun City, Barber County, Kansas Photos from the collection of Kim Fowles.

The following off-site links will open in a new browser window:

"Barber County" +Kansas +Gypsum Search results for books at books.google.com for which the full text of the books is available online.

National Gypsum Company, a company history from answers.com: "In 1937... National Gypsum gained access to a 30 million-ton mine of pure white gypsum near Medicine Lodge, Kansas."

Mining History in Kansas: Interstate Technical Group on Abandoned Underground Mines: "In the south-central part of Kansas, the National Gypsum Company mines the Medicine Lodge Gypsum Member of the Blaine Formation in the upper part of the Nippewalla Group. National Gypsum now mines gypsum primarily by surface mining methods in northwest Barber County; however, they also have a shallow underground mine where they obtain their purest gypsum for high quality plaster. Maximum thickness of the gypsum bed in the area of the mine is about 30 feet."

Petrography of Upper Permian Rocks: "The only active mine in the Blaine formation is located in the Medicine Lodge member southwest of Sun City in Barber County, where the gypsum attains a total thickness of about 30 feet. The mine is operated by the National Gypsum Company, and the rock is processed in a mill at Medicine Lodge. Blaine gypsum has also been mined in other near-by areas. Several abandoned pits may be seen in the vicinity of sec. 19, T. 30 S., R. 15 W., in the northwest corner of Barber County. The gypsum industry in Kansas started in 1872 in Blue Rapids, but the first mill in the southern Kansas area was not built until 1889 (Jewett and Schoewe, 1942, p. 140)."

Special Report on Gypsum and Gypsum Cement Plaster, The University Geological Survey of Kansas. vol.5 (1952): 16, 100-105. Uses of Gypsum in Industry by Roxanne L. Puckett, November 2006.

Natural Resources of Kansas: "In Kansas, gypsum is mined mainly in Barber County, but also in Marshall County (KGS Industrial Minerals in Kansas, 1999). The mining in Barber County is mostly open pit mining where layers of gypsum rock are scraped from the earth's surface. There is also some underground mining done in the area. The Barber County gypsum mine is on of the Nation's 10 largest (Minerals in the 50 States, 1991, p. 18). It is owned and operated by National Gypsum Company and an adjacent plant manufactures wallboard for the construction industry. The plant produces approximately 1.3 million square feet of wallboard and 130 tons of plaster products daily (Medicine Lodge, Kansas: Industry, 2000)."

Thanks to Kim Fowles for arranging the contributions of the photos from Elloise Leffler and Beth (Larkins) Davis which appear on this page.

Copyright © 1996 - The USGenWeb® Project, KSGenWeb, Barber County